Good Shepherd Medical Center – OR AHU

Client Name:

Project Started:

Location:

About Project

Problem:

OR 10-14 and Mechanical Room 1002 AHU-1

Due to its age, condition and lack of serviceability, the existing air handling unit (AHU-1) serving the surgical suites 10-14 at Good Shepherd Medical Center in Longview, Texas is being replaced with a new AHU. The existing AHU is located in a mechanical room on the ground floor while the surgical suite is located on the second floor above. The existing air-handling unit is a constant volume AHU with 6 zones – 5 zones serve operating rooms, with 1 zone serving the surgical corridors and support spaces. The AHU was originally piped to use the hospital plant chilled water, but maintain humidity requirements, when using this chilled water, Therefore, individual glycol coils were added for each zone and an air-cooled glycol chiller system was added to the roof above the mechanical room. The OR’s and AHU are being controlled by an antiquated JCI Metesys control system that needs to be updated.

Solution:

OR 10-14 and Mechanical Room 1002 AHU-1

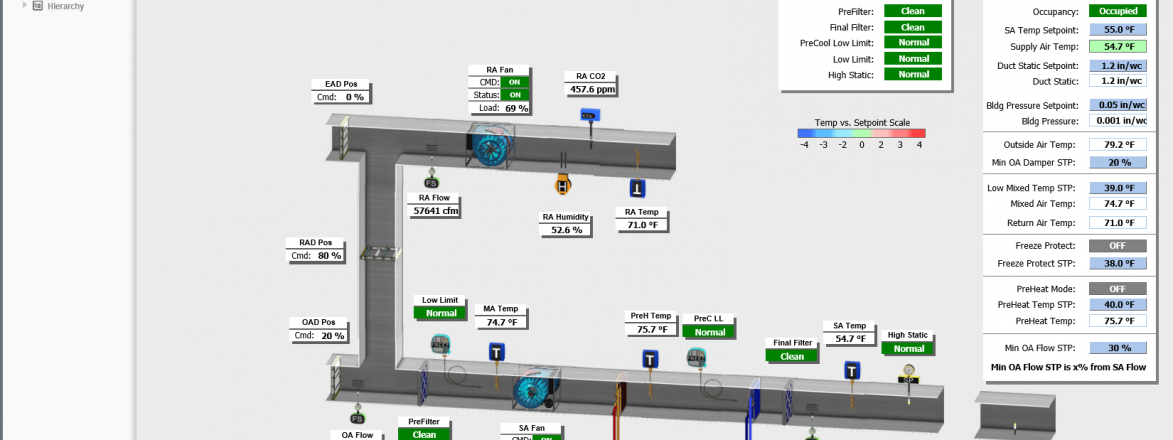

A new air-handling unit (AHU) has replaced the existing AHU, glycol coils and external heap filters. The new AHU is a single-duct supply VAV unit with dual fans, pre-filters, a pre-heat coil, internal glycol coil and final heap filters. This new unit is located in the same mechanical room but relocated 90 degrees perpendicular to the existing unit. This is due to both space constraints in the existing mechanical room and for improved maintenance access.

The new glycol pump will be relocated to give more access to the AHU and new supply ductwork. Each individual zone duct has a damper for air balancing, a hot water VAV box for supply temperature adjustment and an individual electric steam humidifier independent of the house steam system for independent humidity control. The new AHU utilizes a chilled water coil for cooling and is connected to the hospital chilled water system. The second coil is connected to the dedicated glycol chilled water system. This arrangement allows for the majority of the cooling load to be carried by the more efficient hospital chilled water system while also achieving lower supply air temperatures to meet the colder, dryer temperature requirements in the O.R.s. New Niagara controls were added to this project and connected to the new Niagara Web Supervisor along with a thorough Test and Balance.

The major challenges included:

- This project had to be completed in 12 days including controls and test and balance.

- Making sure all Operating Rooms and Sterile Areas met all hospital standards.

- Physically fitting all equipment all equipment to the space and having fully serviceable.

Legacy:

Before completion of the construction project, Good Shepherd Medical Center had entered into a Connected Building Services and Preventative Maintenance agreement. Through the Connected Building Services agreement, we proactively monitor all HVAC units and Sensors so we can react to temperature changes as they occur. When a temperature or humidity deviation is detected, our remote access allows us to troubleshoot the issue and contact Good Shepherd Medical Center for resolution or dispatch a Technician to resolve. Our HVAC Preventative Maintenance program is specifically tailored to the needs of Good Shepherd Medical Center and works in unison with the Connected Building Services agreement. Traditionally preventative maintenance (Quarterly inspections) coupled with the use of BLX TrendView allows us to trend temperatures, humidity and general status of the system. When this data is viewed over time, it allows us to predict failure before it occurs.

Storer Services Individual Responsible for the Project:

- Keith Thompson – Project Manager

- Avery Enders – Programmer

- Keenan Jennings – Account Manager