Problem:

Centenary College has a centralized chilled water/ hot water plant, located under the Library, which serves five campus buildings: the Library, Mickle Hall, Hurley Music Building, Smith Kilpatrick Auditorium and the Chapel. The original plant equipment consisted of an old fire tube boiler and carrier screw chiller that were at the end of their useful life. This equipment was piped to the served buildings in a two-pipe configuration. This piping arrangement created comfort issues as it only allowed them to switch the building from heat-to-cool or cool-to-heat once per year.

Centenary’s original goal was to replace the aged equipment and convert the system to a more modern four-pipe arrangement, which allows for simultaneous heating and cooling, based on occupant requirements. However, the cost for this solution was prohibitive. Centenary approached Storer for a creative solution to the problem.

Solution:

- Storer Services worked closely with Purtle and Associates to develop the solution, which included:

- Replacement of the existing Boiler with three new, high efficient condensing boilers

- Replacement of the existing screw chiller with a new centrifugal chiller

- Major plant re-piping

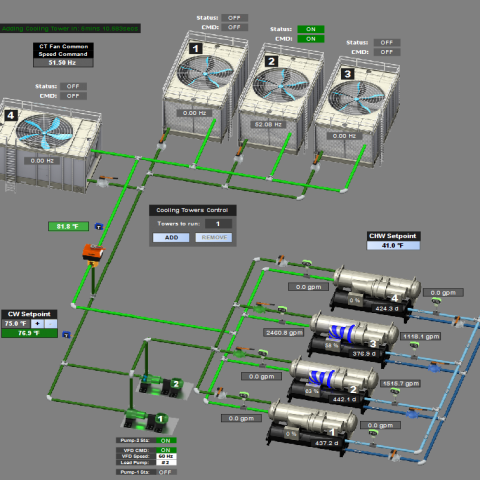

- New DDC control system

The major challenges included:

- Space restrictions- Proper selection and installation of the new equipment was key, in a very small mechanical room.

- Boiler venting restrictions- due the equipment being located in the basement, cutting new roof penetrations was not an option. A common venting system had to be design to ensure the new boilers could vent thru the existing roof penetration.

- Time line restrictions- the entire project had to be completed over Centenary’s Christmas break

- Two-pipe change over system- The budget for the project did not allow for the five buildings to be re-piped to simultaneously heat or cool. Our team’s solution had two major components:

- We arranged the piping and valves inside the central plant to allow the five buildings to be controlled independently. In other words, we gave Centenary the capability to have any one building in cooling while another was in heating. This was a vast improvement to previous operation, which required all five building be in the same mode (heat or cool) at the same time.

- We implemented a programming sequence that minimized the change over timeframe for each building from eight hours to 2 hours without damaging the plant equipment. This was done by utilizing Outside air reset schedules and implementing a sequence of control that allowed the system to add or remove heat without running the water thru the boilers or chillers.

Legacy:

Comfort has been greatly improved for Centenary staff and students that utilize these buildings. Storer continues to assist Centenary in operation and maintenance of the plant through and ongoing Preventative Maintenance and Connected Building Services agreement.